Meeting your demands for infection control

The post COVID-19 healthcare landscape has brought multiple challenges, the most critical being the importance of safeguarding our community and our dedicated healthcare workers. In spite of limited resources, quality and protection in infection control remain non-negotiable.

- Poor product choices around PPE and other medical consumables can negatively impact health and economic outcomes. Managing these consequences requires assessment of barrier protection, adherence to standards, and education in infection control.

- Typical questions include: Which PPE products are the right choice? How do we ensure compliance? What level of fluid resistance is necessary for our specific needs?

- Our commitment to you is grounded in providing answers to these critical questions. As your partner in infection control, we are dedicated to delivering products that rise to meet your exacting standards.

- Formerly part of Kimberly-Clark, HALYARD* is now a part of Owens & Minor, Inc., a globally recognized healthcare solutions company listed on the Fortune 500.

- With a history dating back to 1870, our surgical and infection prevention portfolio focuses on preventing healthcare associated infections (HAIs) and providing protection for healthcare workers and the patients they care for.

- Our global team of over 15,000 dedicated professionals across 70 countries drives our commitment to providing exceptional healthcare solutions across hospitals, adjacent health, and controlled environments.

- Over 100 years of innovation and leadership in infection protection.

- Better Infection Protection Solutions.

- Sourcing only high-quality raw materials for superior product performance.

- Our high quality products meet or exceed industry standards.

- Superior protection against cytotoxic drugs and dangerous chemicals.

- Going the extra mile with exceptional service, training and support.

- Enabling seamless supply.

- Striving to uphold human rights in all our business activities.

- Maintaining recycling rates up to 95% across major manufacturing sites.

Better Infection Protection Solutions

O&M Halyard sells its recognised brands and products in more than 90 countries and holds leading market positions in multiple categories.

The HALYARD* brand is trusted to provide the information, insights and products that are essential for you and your organisation to do what you do best – provide superior patient care.

Sourcing only high-quality raw materials for superior product performance

O&M Halyard strives to provide the highest quality products to support optimal protection for healthcare workers and their patients. With a relentless dedication to quality, our Regulatory Affairs and Quality Assurance teams execute our rigorous internal standards.

Ensuring product safety is critical, and our Product Safety Team plays a pivotal role in achieving this. Employing established risk assessment methodologies, they meticulously evaluate potential hazards and exposures, ensuring that our products are safe, dependable, and compliant with industry standards.

Our assessment process involves:

The highest quality nitrile, NO FILLER

Low quality, low cost gloves are often made with filler ingredients, such as clay or calcium carbonate. Calcium carbonate – commonly known as chalk – irritates eyes, nose, mucous membranes, and skin. Despite this, it remains one of the most widely used low cost fillers in the manufacture of poor quality nitrile exam gloves. Gloves made with fillers are more likely to tear, have quality issues and compromise healthcare worker protection.

HALYARD* Nitrile Exam Gloves are made with only the highest quality raw materials, pass stringent quality controls and are filler free.

Our high quality products meet or exceed industry standards

HALYARD* products are rigorously tested to ensure we meet, and often exceed, industry standards. This assurance provides healthcare workers confidence in protection.

- EN ISO 374-5:2016 Micro-organism and Virus Protection

- EN ISO 374-1:2016/Type C K-Low Chemical Splash Protection

- EN 420:2003 +A1:2009 General Requirements for Protective Gloves

- EN ISO 374-4 Resistance to Degradation by Chemicals

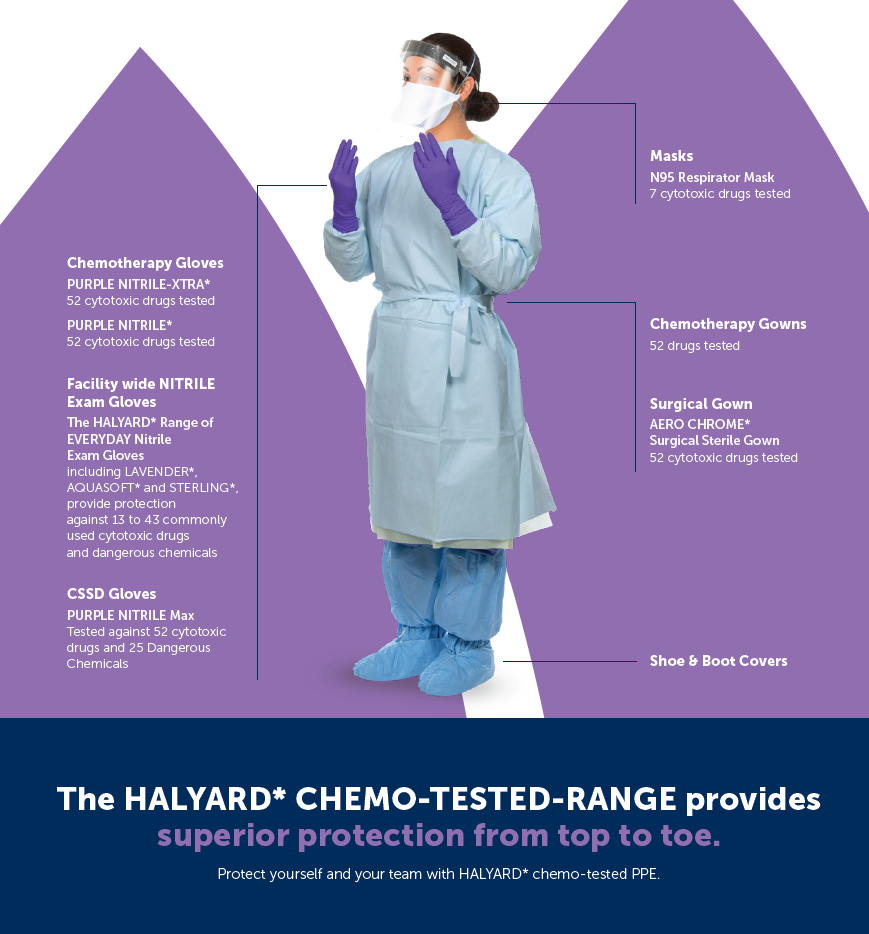

Superior protection against cytotoxic drugs and dangerous chemicals

There is no safe level of cytotoxic exposure for healthcare workers.

Exposure to hazardous chemotherapy drugs increases risks of chromosomal damage, adverse reproductive outcomes, and cancers for healthcare workers. It’s important to consider the long-term health of your staff by minimising the risk of exposure and providing PPE that has been rigorously tested and approved for use with an extensive range of cytotoxic drugs.

HALYARD* PPE and Surgical products are rigorously tested to ensure they meet or exceed standards. Our extensive range of PPE and apparel tested for Chemo includes: Chemo Gowns, Exam Gloves and AeroChrome Surgical Gowns. This level of testing provides superior protection against cytotoxic and dangerous drugs, when you need it most.

Going the extra mile with exceptional service training & support

The HALYARD* brand is recognized worldwide as a leading innovator in quality healthcare products that help reduce infections and protect healthcare workers from contamination. Our commitment to healthcare professionals goes beyond providing quality products. We offer exceptional service training and education to support our customers.

O&M Halyard has a proud history of partnering our innovative clinical products with in-service training, customer support, clinical research, and education to enable healthcare workers to remain at the forefront of best practice and industry trends.

We are committed to exceeding standards and furthering education with one goal in mind, to keep healthcare workers safe.

Striving to uphold human rights in all our business activities

Since our founding in 1882, HALYARD* has remained dedicated to our teammates, our customers, and the communities where we conduct business.

HALYARD’S* social compliance programs strive to uphold human rights in all our business activities.

We adhere to all appropriate policies and procedures, such as:

- Anti-bribery & anti-corruption standards.

- Modern slavery assessments & safeguards (including all forms of involuntary labor, trafficked labor, forced labor and child labor).

- Environmental protections (through risk analysis, training and communication, auditing and monitoring, and our whistleblower hotline).

As our industry continues to evolve, you can count on us to remain constant in our dedication to how we can best serve our teammates, customers, and communities.

Maintaining recycling rates up to 95% across major manufacturing sites

Promoting Environmental Stewardship means reducing the impact of our operations on the environment and includes:

- Reducing climate risk

- Managing our carbon footprint

- Waste and water management

We have adopted practices at our sites to reduce our environmental impact including efforts to reduce waste, manage our carbon footprint, and increase renewable energy usage.

We measure greenhouse gas (“GHG”) emissions, water usage, and waste at our manufacturing sites to set and implement site-specific goals intended to reduce our environmental footprint.

Our manufacturing sites, offices, and distribution centers track the wastes generated at our facilities and direct those wastes to designated recycling locations. These manufacturing sites routinely maintain recycling rates approaching 95%.